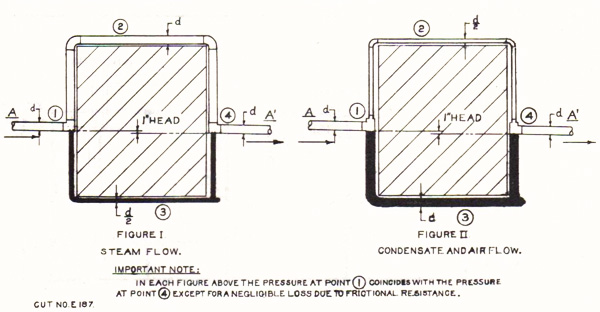

Shown above are conventional solutions to a problem that is frequently encountered on all types of steam heating systems. It is customarily referred to as a “door loop” and has to do with installing a steam supply line or a return line around an obstacle such as a beam, a doorway, or a corridor. The principles involved are important, not only because of the simple applications above, but because the same principles may be applied advantageously to sections of a heating system, or, in fact, to an entire heating system.

Figure I shows a line AA-‘ carrying steam around an obstacle. The steam will flow through the upper line (1-2-4). Any condensate flowing with the steam cannot flow through the upper pipe (1-2-4), but will flow by gravity through the lower pipe (1-3-4). Pipe (1-3-4) will always be filled with condensate up to the level shown. Additional condensate flowing to point (1) will IMMEDIATELY cause an equal volume of condensate to spill over at point (4). Note that point (4) must be about 1 inch below point (1) to provide for gravity flow.

Figure II shows a return line A-A’ carrying condensate and air around an obstacle. The air will flow through the upper line (1-2-4). The condensate cannot flow through the upper pipe (1-2-4), but will flow by gravity through the lower pipe (1-3-4). Pipe (1-3-4) will always be filled with condensate up to the level shown. Additional condensate flowing to point (1) will IMMEDIATELY cause an equal volume of condensate to spill over at point (4). Note that point (4) must be about 1 inch below point (1) to provide for gravity flow.