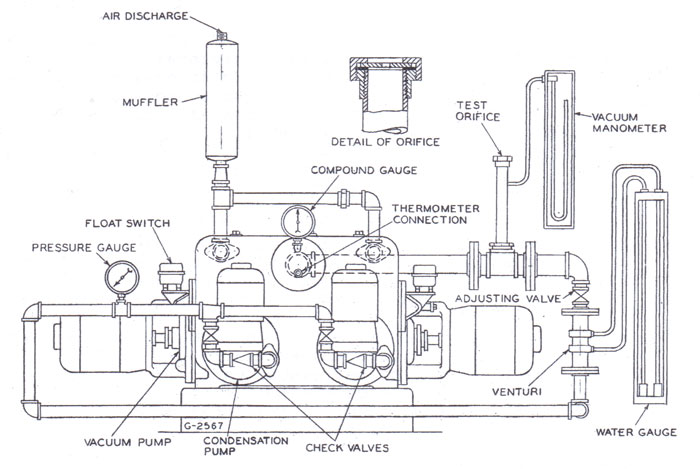

The drawing above shows the factory set-up to test a Nash Jennings Type CSM Vacuum Heating Pump.

Capacity testing in the field does not need to be so elaborate, but the basic principles used in the factory test procedure can still be applied.

CONDENSATE PUMPS

The standard receiving tank sizing is based on the steam condensing rate of the system and provides a one minute condensate storage capacity. If the condensate receiver is sized to this standard, the pump-out time from the start to stop settings of the float switch would be somewhat less than one minute; say 45 to 50 seconds or so. If your on-to-off cycle time is in this range, or less, the condensate pumping function of this unit is meeting the needs of the system.

VACUUM PUMPS

Valving off the receiver tank and testing for maximum vacuum will only show the maximum vacuum the pump is capable of achieving. What’s really needed is knowing the volume flow in terms of cubic feet per minute, CFM.

Frequently vacuum pumps run continuously and never reach the shut off setting of the vacuum switch. This could be due to the vacuum pump being undersized for the load, air leakage into the returning line from atmosphere, condensate that’s too hot, leaking internal valves inside the vacuum pump, worn vacuum pump parts or a combination of factors.

Field testing the air pumping capacity of a vacuum pump is really quite simple. This procedure can be used for any brand or type of vacuum pump. It involves isolating the vacuum pump from the system, pulling air from atmosphere through one or more orifices of known diameter, and recording the resulting vacuum.

It is important when doing this test that the only air flowing into the vacuum pump’s receiver is the air flowing in through the orifice (s).

The metering orifices can be made up from 1″ cast iron pipe caps, drilled and accurately reamed to a specific orifice size. Each orifice should be fitted to a 1″ pipe nipple, 6″ long.

Space does not allow the airflow calculation data. Please contact us for the test orifice size for your particular unit. After your testing is complete, we can tell you the calculated CFM flow rate, and offer advice on your next course of action.