Why Choose A Type CLS Vacuum Heating Pump?

Why Choose A Type CLS Vacuum Heating Pump?

The heart of a vacuum heating pump is… THE VACUUM PUMP.

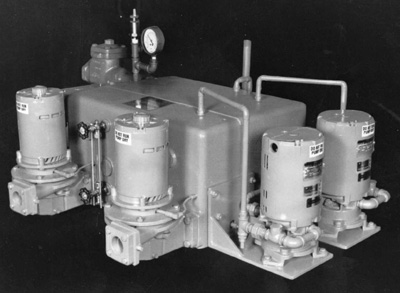

Type CLS Vacuum Heating Pumps employ positive displacement liquid ring vacuum pumps. In terms of CFM per horsepower, they are much more efficient than the water jet type vacuum producer found in other brands of vacuum heating pumps.

Type CLS vacuum pumps are sealed with a gravity flow of recirculated condensate. This simple design means there is no risk of loss of pumping due to loss of prime. A separate seal or hurling water chamber is not used and there is no need for a raw cold water connection, extra float switches, troublesome solenoid valves, internal lift check valves, or spring loaded differential valves. There is no risk of condensate contamination or pump impeller and port blockage due to hard water scale build-up.

Type CLS Vacuum Heating Pumps offer cast iron receivers with a 20 year warranty against corrosion failure. Sizes range from 10 to 500 gallons. The engineer is free to select the receiver size and pumping capacity, which in his judgement, best meet job conditions. Type CLS Vacuum Heating Pumps employ mounted components which means we can “build it your way”. All units are available with control cabinet mounted, wired and tested as complete package.

Alternating water pump control is supplied as standard equipment for all Duplex and Modified Duplex units. This is accomplished with a single mechanical alternating float switch. Under normal operation, the switch alternately operates the right and left water pump. Manual selection of the lead pump is not required. This switch will also operate both pumps under peak load conditions and function as a single switch when only one pump is in service.

Solid state condensate pump alternation with high and low set float switches or Sequence Control with manual selection of the lead and lag condensate pumps is also available.

Full Duplex units with 2 vacuum pumps have primary and back-up vacuum switches with a solid state alternator as standard. Peak vacuum load conditions automatically bring both vacuum pumps into operation until the pre-set shut off point is reached.

Butterfly valves for the condensate pump suction are also available. These allow one pump to be removed from service without the need to shut down and drain the entire unit. Special blanking flanges are not required.

SIZING AND SELECTION OF EQUIPMENT

Receiver

Our Type CLS receivers are sized for an approximate one minute storage capacity. Undersized receivers can cause short cycling and premature wear to motor starting components. Oversized receivers can cause a starve-then-flood condition to the boiler and boiler feed unit.

Type CLS receivers are close grained cast iron. Cast iron is widely recognized as the most durable material. It is not unusual to see cast iron receivers still perfectly sound after more than 80 years of service.

Condensate Pumps

Condensate pumping capacity is directly related to the steaming capacity of the boiler and condensing capacity of the system. One boiler horsepower will evaporate .069 gallons per minute. Each 1000 sq. ft. EDR will condense 0.5 GPM. The usual recommendation is to provide a pumping capacity of 3 times this theoretical condensing rate. This can frequently be reduced to 2 times this rate and still provide ample pumping capacity.

Vacuum Pumps

Unlike condensate pumps or receivers, there is no formula that can be used to calculate air pumping requirements. This can be based only on sound judgement and experience. In years past, for new construction, experience showed that a pumping capacity of 1/3 – 1/2 CFM per 1000 sq. ft. EDR was adequate. This standard can still be used for buildings with tight return piping and no trap leakage.

Recognizing that today’s vacuum-condensate pumps are for installation on existing systems, we recommend 1 CFM of air pumping capacity for each 1000 sq. ft. EDR.

ONE THING IS CERTAIN, IT IS DIFFICULT TO ERR IN PROVIDING TOO MUCH AIR CAPACITY.

Summary of Standard Recommendations For Water and Air Capacities

All values shown below are per 1000 sq. ft. E.D.R for each water or air pumps.

CONDENSATE

Simplex Unit – 1.0 to 1.25 GPM

Duplex and Modified Duplex Units – 1.0 GPM

AIR-FOR LOW VACUUM SYSTEMS

Simplex and Modified Duplex Units – 1.0 CFM

Duplex Units – .75 CFM

AIR-HIGH VACUUM SYSTEMS

Simplex and Modified Duplex Unit – 2.0 CFM

Duplex Units – 1.0 to 2.0 CFM